For numerous years now, micro-LED has been touted as the following huge take into consideration TV tech (and present tech on the whole). Micro-LED tech works similar to the most attention-grabbing OLED TVs in that every pixel emits its non-public light, which means you get pixel-precise distinction with infinitely deep black tones – nevertheless, the pixels might be far brighter than would possibly ever be doable with OLED, and they also must be extra sturdy and longer-lasting.

Nonetheless regardless of being first launched for TVs numerous years to date, there hasn’t been a ton of motion in micro-LED TVs. They’re terribly costly, they usually’re generally solely in the marketplace in very big sizes, principally breaking properly earlier the 100-inch battery (although Samsung managed to get the tech correct proper right into a 75-inch set). And these huge fashions are nonetheless 4K, when you occur to would possibly anticipate the likes of Samsung to make them 8K.

So why hasn’t extra progress been made, and will this modification shortly? I’ve already heard from one huge producer of the tech that it is between 5 and 10 years away from being remotely mainstream, so at a gift Hisense occasion to focus on the corporate’s furthermore huge (nonetheless a lot cheaper than micro-LED) laser TVs (which mix terribly quick throw projection tech with a very matched light-rejection present), I spoke to Dr. Liu Xianrong, Chief Scientist and Elementary Supervisor of Hisense Laser Current, about one of the best ways forward for giant screens.

He outlined that the issue with micro-LED, similar to OLED TVs, is that they’ve some mounted prices and complexity of their manufacturing course of that are not actually diminished by making the fashions smaller, and there is not an apparent option to differ the associated cost and complexity on the horizon – so the economics of growing micro-LED screens could not have the pliability to convey it to the mainstream any time shortly.

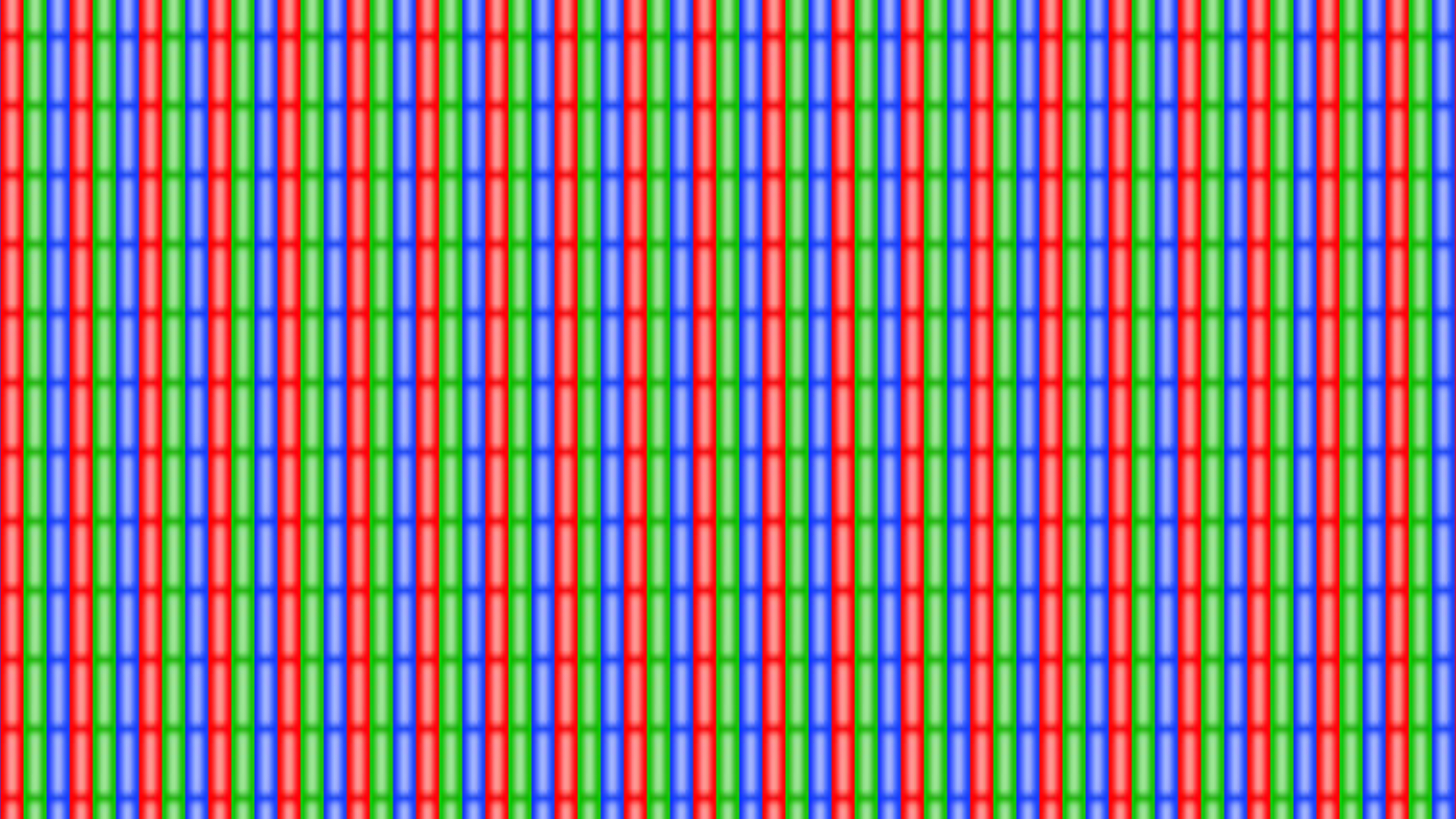

Dr Liu outlined that the issue all through the case of micro-LED TVs is that every pixel is product of three sub-pixels (purple, inexperienced and blue) and that these pixels are created by fully completely completely different firms, and must be launched collectively after which mixed when manufacturing the panel.

The OLED equal to this would possibly most likely be thought-about to be the masking course of, which as quickly as additional requires provides from fully completely completely different locations to be deposited utilizing an elaborate and expensive system, which hasn’t modified a lot on condition that tech launched, as a result of this truth why the value has stayed excessive. Inkjet-printed OLED is meant to be the reply to this in OLED’s case, nonetheless we have been promised that tech is solely all through the nook for a very very very long time (although TCL CSOT, the present manufacturing and enchancment arm of TCL, says it actually is rolling this tech out now for smaller screens).

Amusingly, it is doable to make very small micro-LED screens with terribly excessive pixel density – assume one issue designed for the most attention-grabbing smartwatches – together with very big micro-LED screens, nonetheless getting one issue made all through the center is the place it falls aside, nonetheless that is what we actually want for lots of TVs.

Separation of powers

Dr Liu talked about there’s one completely different complication with micro-LED TVs in enchancment, although, that stems from the fact that the pixels do all of the work for each the brightness and the colour. Within the occasion you need to make a processing adjustment to the brightness, you may’t assist nonetheless influence the colour, and vice versa. It makes the whole panel terribly troublesome to deal with wanting good, as quickly as additional affecting how pricey the whole system is to develop and produce.

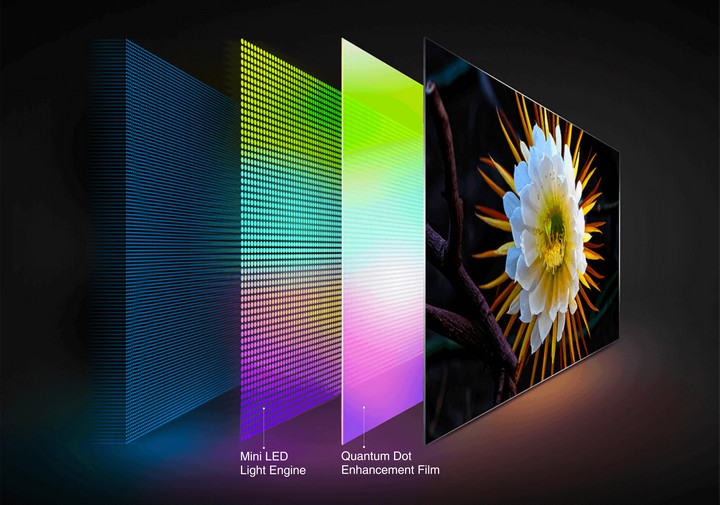

In most TV tech, together with mini-LED, laser TV and OLED when used on TVs, there are separate parts which can assist mitigate this. Mini-LED makes use of a web-based of tiny LED lights to generate the brightness, behind a color-changing array of pixels (generally utilizing quantum dots). You most likely can administration these parts individually to compensate for any modifications you might have purchased made to the choice one and shield factors mounted. QD-OLED is comparable, in {{{that a}}} layer of blue/inexperienced OLED pixels sits behind a quantum dot color-filter layer.

And whereas laser TVs deal with shade and brightness multi function from the projector, the present is part that may very well be developed individually to assist enhance brightness, say – Hisense packs an ambient light-rejecting present with its laser TVs which can roughly double brightness as in contrast with a fundamental present – so you may nonetheless use the fact that they’re separate to assist with refining the image.

Packing the entire points correct proper right into a set of RGB sub-pixels for micro-LED provides complexity that positively might be overcome (OLED cellphone screens use an RGB sub-pixel growth), nonetheless as quickly as additional it merely components into why the TVs are prone to stay costly, and why it will be gradual for that to vary.

Micro-LED and mini-LED have been truly launched to the world on the same time – Samsung launched its first mini-LED and micro-LED TVs at the very same occasion. Nonetheless the most attention-grabbing mini-LED TVs have dropped shortly in worth in order that in its place of being in elite TVs solely, the tech is now in the marketplace in actually good low-cost fashions, such on account of the Hisense U6N and TCL C805 (UK and Europe solely).

Micro-LED appears to be prefer it’s a pleasant distance from having that very same breakthrough low-cost second, though huge TVs have gotten an rising number of regular, which must be very best for it. It most definitely continues to be the following huge take into consideration TVs; merely do not anticipate ‘subsequent’ to be merely all through the nook.